Vast experience meets ambitious vision.

Home / News / What are the problems with fiber optic splice boxes?What are the problems with fiber optic splice boxes?

2022.06.23

At present, the optical fiber splice boxes on the market mainly have the following problems:

1. Cut corners and shrink the shell to reduce costs. The standard stipulates that "the length of the remaining optical fiber of the optical fiber cable can be provided inside the optical fiber splice box is not less than 1.6m, and the bending radius of the remaining optical fiber reel should not be less than 37.5mm", and requires the operator to have enough operating space, so that It is required that the interior of the optical fiber splice box should not be too small, some boxes are very small, and it is difficult to meet the standard requirements if the capacity is large;

2. Reduce the number of accessories that should be configured, and some test functions cannot be operated. Some optical fiber splice boxes are basically not equipped with grounding lead-out devices (in order to ensure good grounding, this piece is made of copper), so that the optical fiber splice boxes do not have the function of grounding and cannot guarantee the safety of the ring network; some optical fiber splice boxes are not equipped with inflatables. The air nozzle (made of stainless steel material) cannot be tested for sealing performance, and of course it cannot be said that the sealing performance is good or bad. At present, there is a combination of grounding and inflation, which is the performance of wanting to reduce costs by reducing configuration.

3. Use other engineering plastics instead to reduce costs. The polycarbonate and alloy PP mentioned above are relatively expensive engineering plastics, and some manufacturers replace them with low-cost materials, which reduces the single cost of the optical fiber splice box, but this will bring about more unqualified performances~ For example, poor material fluidity will cause defects in injection molding, cracking under certain conditions, and excessive addition of auxiliary materials will accelerate aging, etc., which will have a greater negative impact on the entire project.

Hangzhou Zhongling Technology Co.,Ltd. is a Famous China OEM Dome Fiber Optic Splice Closures Manufacturers and wholesale Fiber Dome Splice Closures Suppliers, It is located in Yuyao city -”Literature of the state”. Factory transportation is convenient, close to 329 National Road and only 1 hour to Ningbo or Hangzhou Airport .The factory covers more than 10,000 square meters , with Large,medium,small various specification of injection machine ,Multi purpose CNC laser cutting machine,CNC bending machine,CNC plate shears,CNC control,Welding machine,Riveting machine and etc,dozens of Finishing machinery and equipment.Meanwhile, the factory has a set of spray line to produce all kinds of Safe. The factory covers more than 10,000 square meters , with Large,medium,small various specification of injection machine ,Multi purpose CNC laser cutting machine,CNC bending machine,CNC plate shears,CNC control,Welding machine,Riveting machine and etc,dozens of Finishing machinery and equipment.Meanwhile, the factory has a set of spray line to produce all kinds of Fiber Dome Splice Closures Wholesale. The main products of our company include : Office safe, Family safe,Hotel safe and Gun safe. The company has a rich experience for new product design, R&D, quality control,production , inspection,sales and service.

Hangzhou Zhongling Technology Co.,Ltd. is a Famous China OEM Dome Fiber Optic Splice Closures Manufacturers and wholesale Fiber Dome Splice Closures Suppliers, It is located in Yuyao city -”Literature of the state”. Factory transportation is convenient, close to 329 National Road and only 1 hour to Ningbo or Hangzhou Airport .The factory covers more than 10,000 square meters , with Large,medium,small various specification of injection machine ,Multi purpose CNC laser cutting machine,CNC bending machine,CNC plate shears,CNC control,Welding machine,Riveting machine and etc,dozens of Finishing machinery and equipment.Meanwhile, the factory has a set of spray line to produce all kinds of Safe. The factory covers more than 10,000 square meters , with Large,medium,small various specification of injection machine ,Multi purpose CNC laser cutting machine,CNC bending machine,CNC plate shears,CNC control,Welding machine,Riveting machine and etc,dozens of Finishing machinery and equipment.Meanwhile, the factory has a set of spray line to produce all kinds of Fiber Dome Splice Closures Wholesale. The main products of our company include : Office safe, Family safe,Hotel safe and Gun safe. The company has a rich experience for new product design, R&D, quality control,production , inspection,sales and service.

related product

-

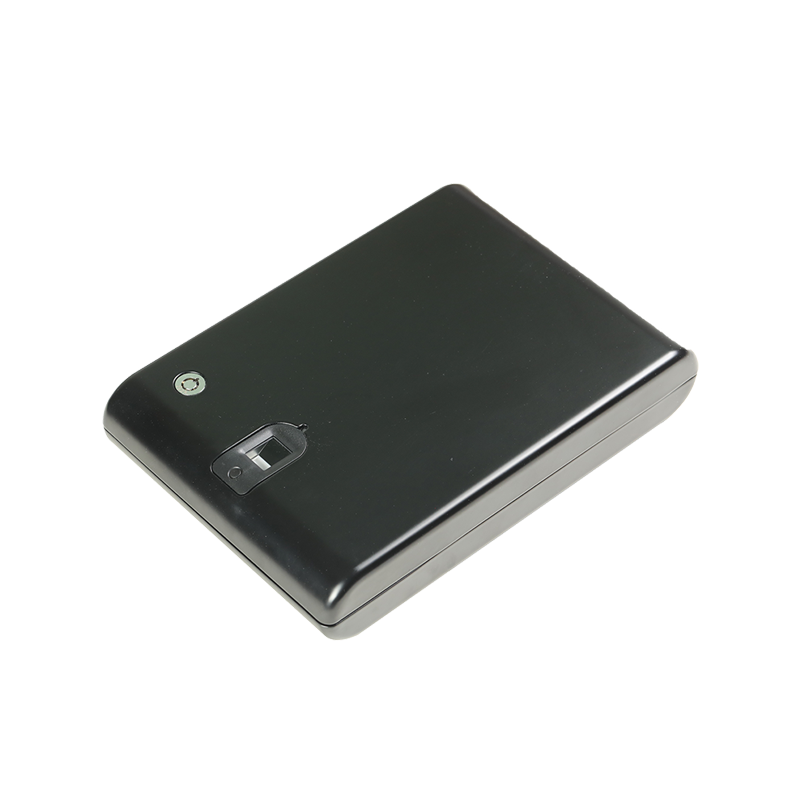

Fingerprint Reader Office / Home Safe

ZLS-808

-

Digital Keypad Office / Home Safe

ZLS-810

-

Digital Code Handgun Box

ZLS-814

-

Fingerprint Reader Handgun Box

ZLS-817

-

Digital Touch Screen Office / Home Safe

ZLS-823

-

Fingerprint Reader Office / Home Safe

ZLS-825

-

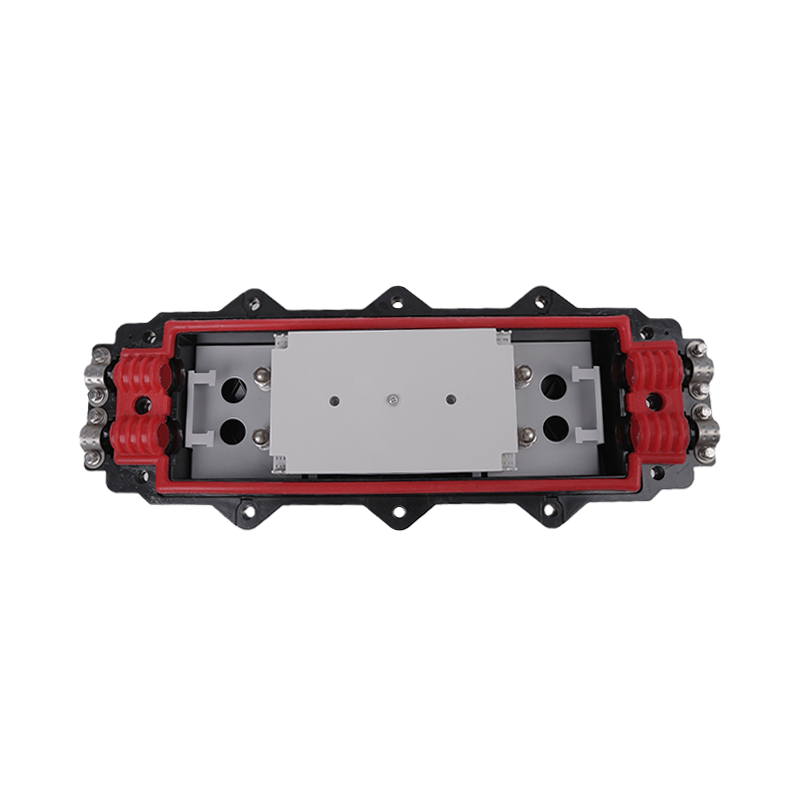

Horizontal Fiber Optic Splice Closure 209F

-

Dome Fiber Optic Splice Closure 208-3

GET STARTED TODAY ?

We Can Help You With

There are many variations of safe, but the majority have services for all types and sizes.

英语

英语 中文简体

中文简体