Vast experience meets ambitious vision.

Home / News / How to solve the problem of water in the optical fiber connectorHow to solve the problem of water in the optical fiber connector

2022.06.02

According to the analysis of the case of the connector in use, we found that the main reasons for the water entering the closed part of the optical fiber connector are as follows:

1. In use, the fiber optic splice closure consists of two symmetrical and similar parts. There are two ways to enter the water in the optical fiber splice box, one is the light inlet of the optical fiber splice box, and the other is the contact end face of the upper and lower parts. The former is sealed by wrapping a strip of sealant over the cable jacket. The end face seals are sealed with rubber strips. The wire inlet hole is divided into two semicircles by the end face, which belong to the upper box and the lower box respectively. This will cause the cable to get in. The in-situ seal interacts with the box end face seal and restricts each other. When the construction personnel are required to seal the cable inlet L at both ends of the optical fiber splice box with tape, the quantity of sealing tape must be strictly used. When the amount is too small, the feed through holes will create gaps and cause water ingress. When the glue is tangled too much, both ends of the junction box will become high, and moisture will enter through the glue strips from the connecting end faces of the upper and lower parts of the junction box. In addition, when there is more sealant on one side and less sealant on the other side, the heights of the two ends of the splicing box may be inconsistent, and a gap may be formed on the contact surfaces of the upper and lower boxes, resulting in water inflow.

2. It is unreasonable to use sealant at the closure of the optical fiber connector of the optical cable entrance. The sealing of the cable gland to the junction box is achieved by a sealant wrapped around the cable. This extrusion imparts pressure to the sealant perpendicular to the cable, but the adhesive is not in the axial direction of the cable. .This causes the sealant to extend along both sides of the optical cable after being pressed, so that the adhesive cannot make sufficient contact with the optical cable, the adhesive and the casing, and a good sealing effect cannot be achieved.

3. Since the sealant is not under enough pressure and both ends are exposed, its stickiness and elasticity will decreaseover time until it hardens.

Hangzhou Zhongling Technology Co.,Ltd. is a Famous China OEM Fiber Optic Splice Closures Manufacturers and wholesale Fiber Optical Splice Closures Suppliers, It is located in Yuyao city -”Literature of the state”. Factory transportation is convenient, close to 329 National Road and only 1 hour to Ningbo or Hangzhou Airport .The factory covers more than 10,000 square meters , with Large,medium,small various specification of injection machine ,Multi purpose CNC laser cutting machine,CNC bending machine,CNC plate shears,CNC control,Welding machine,Riveting machine and etc,dozens of Finishing machinery and equipment.Meanwhile, the factory has a set of spray line to produce all kinds of Safe. The factory covers more than 10,000 square meters , with Large,medium,small various specification of injection machine ,Multi purpose CNC laser cutting machine,CNC bending machine,CNC plate shears,CNC control,Welding machine,Riveting machine and etc,dozens of Finishing machinery and equipment.Meanwhile, the factory has a set of spray line to produce all kinds of Fiber Optical Splice Closures Wholesale. The main products of our company include : Office safe, Family safe,Hotel safe and Gun safe. The company has a rich experience for new product design, R&D, quality control,production , inspection,sales and service.

Hangzhou Zhongling Technology Co.,Ltd. is a Famous China OEM Fiber Optic Splice Closures Manufacturers and wholesale Fiber Optical Splice Closures Suppliers, It is located in Yuyao city -”Literature of the state”. Factory transportation is convenient, close to 329 National Road and only 1 hour to Ningbo or Hangzhou Airport .The factory covers more than 10,000 square meters , with Large,medium,small various specification of injection machine ,Multi purpose CNC laser cutting machine,CNC bending machine,CNC plate shears,CNC control,Welding machine,Riveting machine and etc,dozens of Finishing machinery and equipment.Meanwhile, the factory has a set of spray line to produce all kinds of Safe. The factory covers more than 10,000 square meters , with Large,medium,small various specification of injection machine ,Multi purpose CNC laser cutting machine,CNC bending machine,CNC plate shears,CNC control,Welding machine,Riveting machine and etc,dozens of Finishing machinery and equipment.Meanwhile, the factory has a set of spray line to produce all kinds of Fiber Optical Splice Closures Wholesale. The main products of our company include : Office safe, Family safe,Hotel safe and Gun safe. The company has a rich experience for new product design, R&D, quality control,production , inspection,sales and service.

related product

-

Digital Touch Screen Office / Home Safe

ZLS-806

-

Digital Code Handgun Box

ZLS-814

-

Digital code Handgun Box

ZLS-815

-

Solid Wood Construction 3 Drawer Mobile File Cabinet

ZLS-822

-

1 fiber Fiber optic socket GFS-1A

-

Optical Fiber Adaptor ST

-

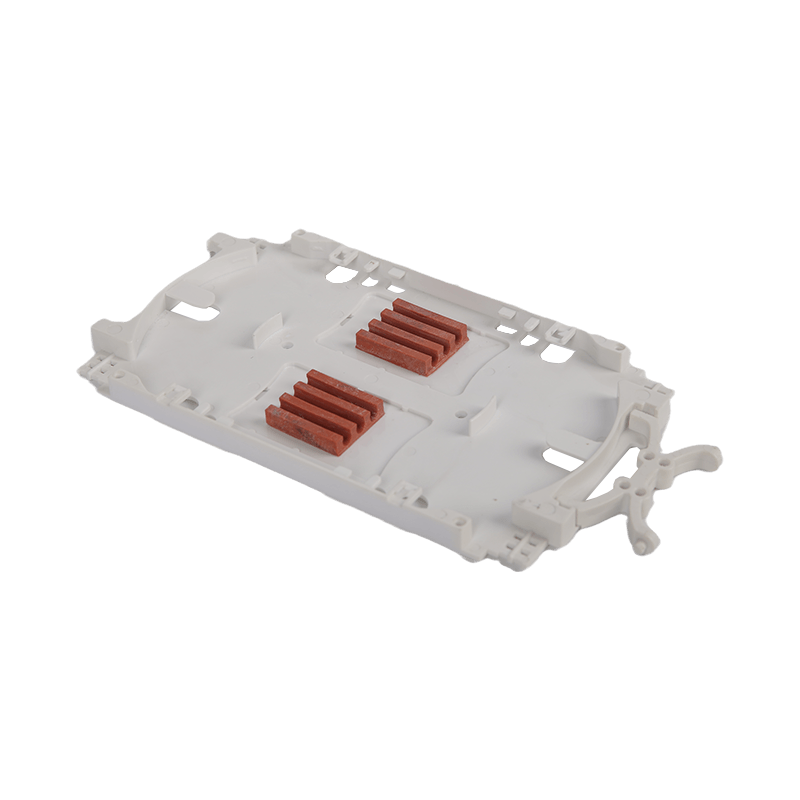

Splice tray-ribbon 72 cores 208-2D-XP

-

Horizontal Fiber Optic Splice Closure 209-2Single Height

GET STARTED TODAY ?

We Can Help You With

There are many variations of safe, but the majority have services for all types and sizes.

英语

英语 中文简体

中文简体